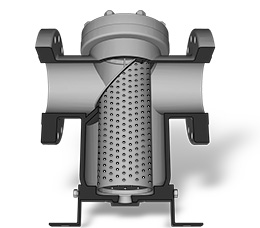

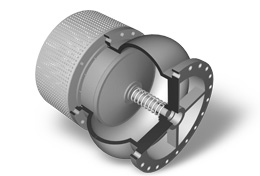

Y Strainers

Y Strainers (or "Wye Strainers") mechanically remove debris in pipeline with a cylindrical straining element, often called a screen. They can be placed in horizontal or vertical pipelines (downward only) and require regular cleaning of the screen for proper operation.

Features of Titan Y Strainers

- All Titan Cast Iron and Carbon Steel strainers are epoxy painted providing an increased resistance to rust and corrosion.

- Hex ends on threaded units allow for quick and easy installation.

- Finer filtrations are possible with precision machined screen seats in both the body and the cap. This also helps to ensure proper alignment during assembly.

- Encapsulated gaskets extend the life of the gaskets and aid in preventing a gasket blowout.

- Large strainer bodies provide a large open area ratio that minimizes pressure drop.

- Drain/Blow-off plugs are provided at no additional cost on applicable models. Blow-off valves can be installed in-house to enable self-cleaning and reduce maintenance time at the job site.

- Numerous straining element options are available (perforation, mesh, and material) and Titan can quickly provide replacements when needed.

Basket Strainers

Basket strainers are used to mechanically remove debris in pipelines with a straining element that is shaped like a basket. Basket Strainers are typically used in horizontal pipelines. In most cases, they provide more open area for debris collection than a Y strainer and need less frequent cleaning.

Features of Titan Basket Strainers

- All Titan Cast Iron and Carbon Steel strainers are epoxy painted providing an increased resistance to rust and corrosion.

- Hex ends on threaded units allow for quick and easy installation.

- Finer filtrations are possible with precision machined screen seats in both the body and the cap. This also helps to ensure proper alignment during assembly.

- Encapsulated gaskets extend the life of the gaskets and aid in preventing a gasket blowout. Models that offer an over-the-top flow path also feature a basket/seat o-ring.

- Optional cover designs are available including bolted, quick-open, and more.

- Large strainer bodies and sizable straining elements provide a large open area ratio that minimizes pressure drop and maximizes time between servicing.

- Drain and cover vent plugs are provided at no additional cost on applicable models. Blow-off valves can be installed in-house to enable self-cleaning and reduce maintenance time at the job site.

- Numerous straining element options are available (perforation, mesh, and material) and Titan can quickly provide replacements when needed.

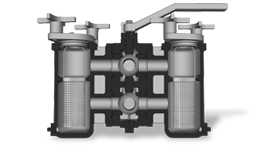

Duplex Strainers

Titan’s Duplex Strainers are high quality, compact units, ideal for non-interruptible applications. They are easy to operate and maintain with no special tools required to remove the straining element from the chamber. Two basket chambers and a flow diverter system allow the pipeline flow to be switched from one chamber to the other, isolating the flow to a single chamber and allowing the inactive chamber to be cleaned without shutdown. Titan Duplex Strainers are available with threaded and flanged ends in a variety of materials. All cast iron and carbon steel units are epoxy painted to resist rust.

Features of Titan's Duplex Strainers

- Easy to Operate - Titan FCI's Duplex Strainer features a low torque, easy to operate handle that does not require a gearbox

- Reduced "In-Line" Maintenance - The dual/quad ball design isolates each chamber and keeps the servicing chamber dry during cleaning, an no special tools are required to access and remove the straining element from the chamber.

- Endless Screen Options - This strainer can be fitted with virtually any configuration of perforation or mesh lined straining elements. Straining elements can also be constructed from special materials such as Alloy 20.

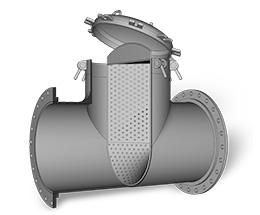

Fabricated Products

An Example of a Titan Fabricated Tee Strainer

Fabricated products provide additional flexibility and design options for unique applications. Our highly experienced engineering team and fabrication department is customer-focused and detail-oriented, ensuring that a Titan fabricated product will not only meet the needs of your application, but will be of the highest quality.

Titan FCI can provide fabricated products that are non-code, National Board Certified, ASME "U" Code Stamped, and ASME "UM" Code Stamped.

Common Fabricated Products

| Temporary Strainers | Spectacle Flanges |

| Plate Strainers | Single Blinds |

| Orifice Plates | Ring Spacers |

| Bleed Rings | Steam Jacketed Strainers |

Fabricated Wye, Tee, Duplex, and Basket Strainers

| Hand- and Motor-Operated Fabricated Specialty Strainers |

Check Valves

Check Valves are automatic shut-off valves that are commonly used for preventing backflow or drainage in a piping system. Often applied on the discharge side of pumps, check valves prevent the system from draining if the pump stops and protect against backflow, which could harm the pump or other equipment.

Titan Flow Control, Inc. offers a variety of check valve designs to meet your specific needs including Center-Guided Globe Style Valves, Center-Guided Wafer Style Valves, Center-Guided Threaded Valves, Dual Disc Check Valves, and Single Disk Check Valves.

Butterfly Valves

Butterfly Valves are lightweight, quarter-turn valves used for regulating or isolating pipeline flow. Titan Flow Control offers them in Wafer (Cast Iron) and Lug (Ductile Iron) styles.

Features of Titan's Butterfly Valves

- Cast-in actuator flange is universally designed in accordance with the ISO 5211 to accommodate a variety of actuators. Titan offers a complete line of Pneumatic and Electric Actuators.

- Extended neck provides clearance for 2" of piping insulation.

- The one-piece through stem design offers exceptional strength, stability, dependability, and accurate disc positioning.

- Ten position handle allows disc to be positioned with accuracy.

- Phenolic Backed Cartridge Seat allows for higher vacuum and velocity service when compared to soft seats.

Pump Protection and Other Specialty Products

Titan Flow Control provides additional products to protect expensive pipeline equipment:

Suction Diffusers

Titan Flow Control's Suction Diffusers function as strainers, helping to prevent debris from harming a pump. They save space, maintenance time, and money as they replace a 90 degree elbow, a strainer, and an entry pipe. Straightening vanes reduce turbulence in the flow and alleviate stress and erosion on the pump.

Tri-Flow Control Check Valves

Tri-Flow Control Check Valves are spring-loaded valves that can be adjusted from full flow to complete shut-off. They function as balance valve, shut-off valve, and a check valve.

Foot Valve Assemblies

A foot valve is a special type of check valve that has a built-in strainer. Foot valves are installed at the intake side of a suction pipe and pump, preventing the loss of prime when a liquid source is lower than the pump and helping to remove unwanted debris from the liquid that may damage the pump.

And Much More!

At Titan Flow Control, we will honestly tell you what we can do for you and what we cannot do. With over 300 years of combined experience in the pipeline industry, we are capable of providing you with solutions for the most unique piping requirements and applications. If you are looking for something you do not see on our website, please ask us!